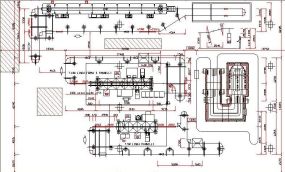

Below a typical enameling plant layout for cooker panels & ovens, based on electrostatic powder application technology and 2 coats / 2 fire enameling process for parts in light colors, which fits in a building of 50 x 20 meters.

Pretreatment

Products are first pretreated with a warm alkaline degreaser in a spray washer,

while being suspended to an overhead conveyor.

After the degreasing stage, the products are rinsed with normal water or demi

water in case of hard water. The last stage of the

pretreatment process is

drying at circa 150 degree Celsius in a U-type convection dryer. The products

are now free of oil & mechanical dirt.

Application

Products are suspended to the next overhead conveyor and pass thru a

powder

booth, where powder enamel particles are sprayed electrostatically. Thanks to

the electrostatic charge powder particles stick to the substrate and allow

transfer to the furnace conveyor. Any oversprayed enamel is automatically

recycled and sprayed again. In this way an almost perfect material utilization

is achieved.

Firing

At the enameling furnace

the dry enamel film, which thickness range between 90 and 220 microns depending upon the utilized

enameling process, is cured at a temperature between 800 and 830

degree Celsius.

Turnkey solutions

Ditmer Trading & Consulting B.V. is specialized to provide independent

consultancy and/or project management to enable trouble-free realization of complete enameling plants on a turnkey

base. Click here

for our contact details.

Below some pictures of the above described enameling equipment