Benefit from our knowledge & experience !

Industrial enameling plant lay-outs

Industrial enameling plant lay-outs

An enameling plant is more then a collection of enameling equipment.

Its layout may have a significant effect on the achieved coating quality,

operational enameling cost and ease of future maintenance.

Please find below some simplified examples of enameling plant lay-outs

for various products, such as cookers, water heaters and sanitary ware.

Related services

Management consulting

Setting-up new enameling plants

Layout design & optimalisation

Material flow improvement

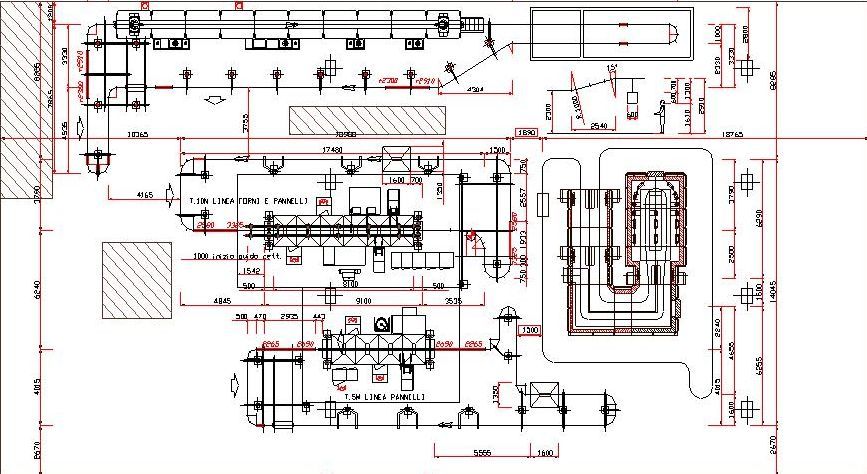

Cookers / Ranges

Modern cooker enameling plant with spray-degreasing tunnel and powder application equipment.

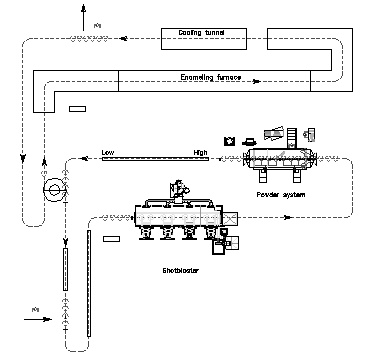

Electrical water heaters

Compact offline powder enameling solution with a capacity of 30 - 45 electrical boilers per hour.

Solar boilers / Geysers

Online powder enameling solution with Power + Free conveyor and automatic transfer device for large electrical & solar heated boilers.

Related links

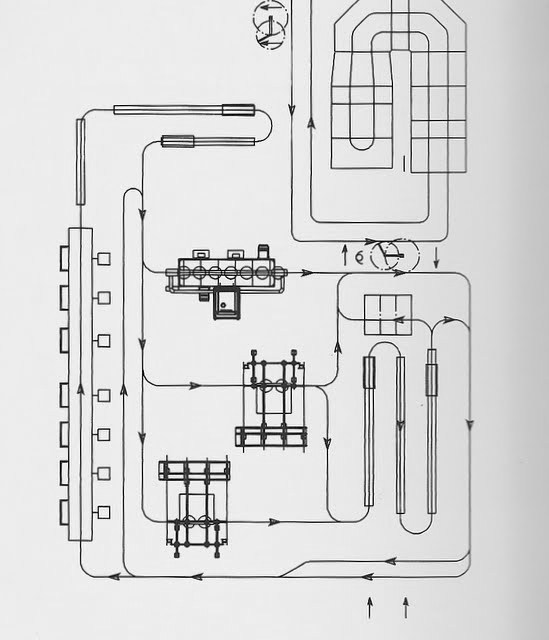

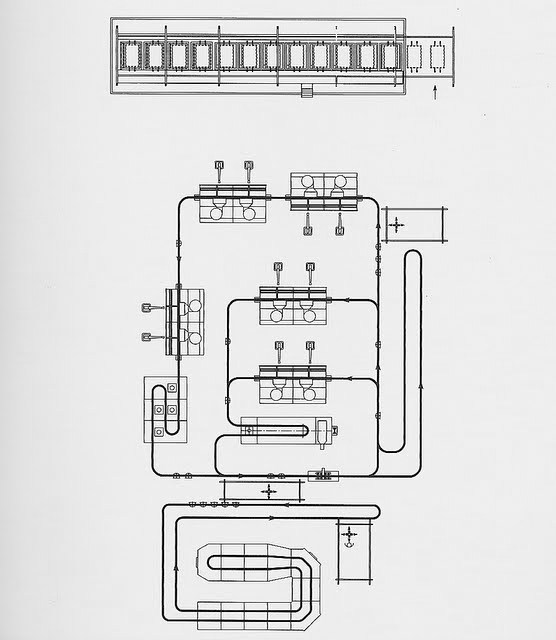

Hot water tanks (HWT)

Example of a highly automated flexible enameling plant for large water heaters, boilers & hot water tanks. Using spray pretreatment, advanced P+F conveyors and multiple application technologies.

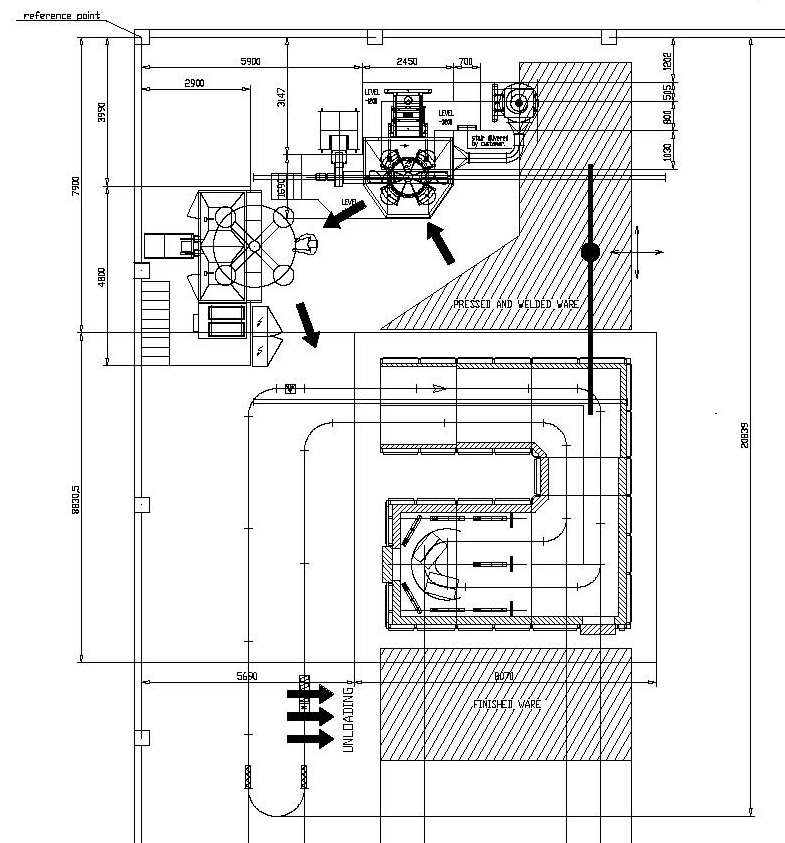

Sanitary ware

Above an example of an industrial enameling plant for bath-tubs and shower basins with full pickling, Power+Free conveyor system and wet enamel application with robots.

About Us

Ditmer Trading & Consulting BV is a family owned company, which was founded by Ronald Ditmer in 2007.

We are specialized in providing worldwide professional services & supplies to the porcelain (vitreous) enameling industry.

Benefit from our experience

Our Managing Director & Owner has been personally involved in 50+ industrial porcelain enameling projects since 1984, while working respectively for Ferro (Holland) BV, Smit Ovens BV, Smit Sinus Enameling BV, Nordson Corporation and/or Ditmer Trading & Consulting BV.

Company details

Ditmer Trading & Consulting BV

Palissander 141

3315MP Dordrecht

The Netherlands

Phone :

+31-78-6169877

e-mail : info@ditmer.nl

for further information and/or assistance