| Home > Enameling > Equipment > Wet application equipment |

Porcelain enamel may be applied via a variety of wet application methods, such as dipping, flow-coating, slushing and spraying.

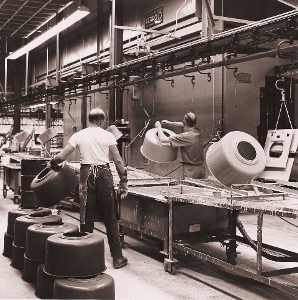

Originally application of porcelain enamel was done manually, as shown at the pictures below.

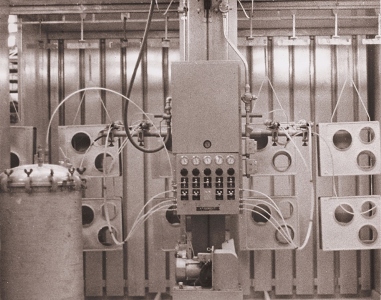

With increasing labor cost and production volumes, manual application was replaced by automatic application. In order to reduce enameling cost and/or improve the coating quality, more advanced applications systems, such as electrostatic wet spraying, robot spraying and electrophoresis, where introduced in the 50's and 60's.

Nowadays wet enamel is typically used for small production runs (of special colors), special enamels and/or when the product design isn't suitable for electrostatic dry application.

Well-know liquid enamel application equipment producers include : Binks, Devilbiss, EIC, Eisenmann, Fisher, Sames, VGT.

DTC may assist you to evaluate, which application method and/or equipment is most suitable for your products, and if required also help you with sourcing / procuring the appropriate machines.

Related topics :

Tags : wet, liquid, enamel, application, spraying, dipping, flow-coating, slushing, equipment, machine.

---