Benefit from our knowledge & experience !

Ditmer Trading & Consulting BV

Professional Services & Supplies

Porcelain/Vitreous enamel defects

Resolving enamel defects

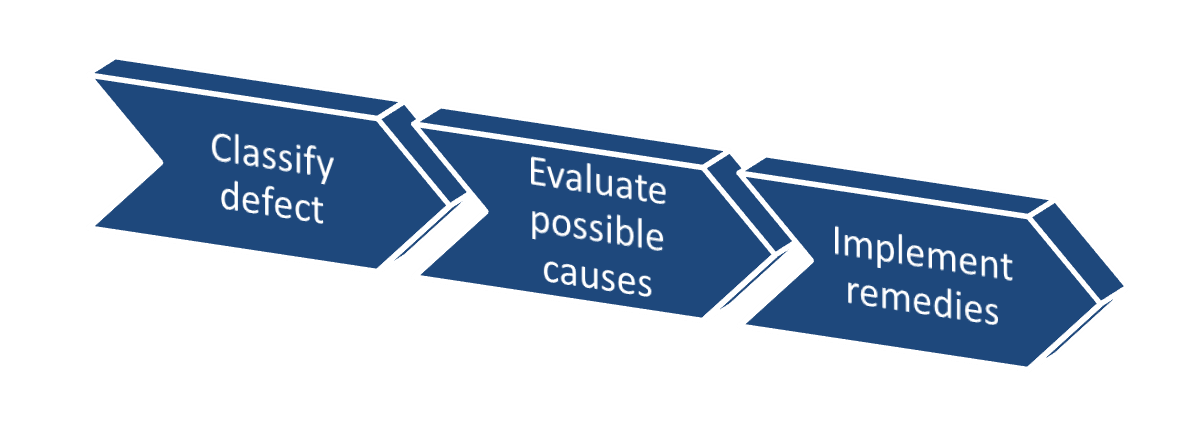

Resolving one of abovementioned enamel defects during an industrial manufacturing process requires a structured three steps approach.

| Step I | Identify the right defect. This may sound silly, but it is sometimes not easy to determine what is the exact defect. Incorrect identification will lead to the wrong causes & remedies. |

| Step II | Evaluate possible causes. Focus your attention on the most logical ones first. |

| Step III | Implement appropriate remedies. |

Due to the relative complex nature of enameling processes, it might not be easy to resolve an enamel defect.

Please feel free to contact us, via the form below, if you require any further information and/or assistance.

Contact Us

More about enameling

Related literature :

Atlas of Enamel Defects

Comprehensive manual with pictures, descriptions, possible causes & remedies of common enamel defects.

Porcelain (Vitreous) Enamels

and Industrial Enamelling Processes

This reference book is a must for every enamelist !

Include among others Ishikawa cause and effect diagrams for most defects.

Pemco

This manual covers many aspects of industrial enameling and is therefore interesting for a large audience.

About Us

Ditmer Trading & Consulting BV is a family owned company, which was founded by Ronald Ditmer in 2007.

We are specialized in providing worldwide professional services & supplies to the porcelain (vitreous) enameling industry.

Benefit from our experience

Our Managing Director & Owner has been personally involved in 50+ industrial porcelain enameling projects since 1984, while working respectively for Ferro (Holland) BV, Smit Ovens BV, Smit Sinus Enameling BV, Nordson Corporation and/or Ditmer Trading & Consulting BV.

Contact details

Ditmer Trading & Consulting BV Palissander 141 3315MP Dordrecht The Netherlands

Phone : +31-(0)78-6169877

e-mail : info@ditmer.nl

Palissander 141, 3315 MP Dordrecht, The Netherlands | e-mail: info@ditmer.nl | Phone : +31-786169877 | WhatsApp : +31-638-508743