| To maintain the reproducibility of your enameling process, it is important to monitor and control all major process parameters. With regard to the electrostatic powder enamel application department, it is necessary to keep your ambient conditions, equipment settings and powder properties within strict tolerances. This web page focus on the powder properties of porcelain enamels, which may be characterized by the following parameters :

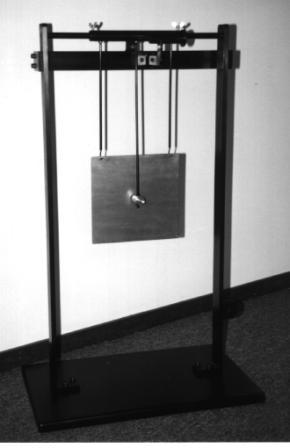

AdhesionAdhesion checks are most probably the best indicator of the condition of the powder.The adhesion of a powder is usually tested by applying a normal coating on a panel at standard settings. After a certain time interval, the panel is subjected to an impact of a controlled force, which is reproducible.

The only difference between the STPA and LTPA method is the duration of the time interval between powder application and impact. (1 minute versus 15 minutes)

Application RateThe application rate of powder is generally used to determine the rate of material transfer.It may be measured by determining the gun output per unit of time and then using that value as a denominator for the amount of powder applied to a standard target at a given time. Application rate = ( grams on target / grams output from gun ) x 100 % Sources : Back to top of document Particle size distributionThe gain size spectrum has a considerable influence on its electrostatic charging and aerodynamic characteristics.The share of coarse particles in a powder enamel can be determined by means of the Bayer test sieve with for example a screen aperture of 0.04 mm. (= 40 mu = 16900 mesh/cm2) The residue of powder (RP) in percentage by weight is a measure for the frequency of coarse particles. Since the powder particle size distribution is a "normal" distribution, the one point check is usually satisfactory for determining the acceptability of a powder. However, please note that the gain size distribution may be altered if the powder recovery at the application system is defective.

Back to top of document Fluidity of powderThe fluidity of a powder (its ability to get whirled up in a gas stream) can be measured with a fluidimeter.The average outflow of powder in grams per sec are a good indication of a powder's fluidity.

DTC is specialized in providing enameling process & equipment knowledge and practical project support to customers worldwide. If required, we may assist you with sourcing the above mentioned equipment for testing powder enamel. For more info please contact us

Tags : powder, enamel, test, testing, equipment, instrument |