Benefit from our knowledge & experience !

Porcelain/Vitreous Enamel Defects

Professional Services & Supplies

Enamel defects

Below a list of possible enamel defects, which may occure during industrial enameling, and a short description of their appearance(s)

Back-emission - Localized heavy wavy surface with in extreme cases star shapes.

Back-ionization - See back-emission

Bisque damage - Excessive area of oxidation at direct-on processes or groundcoat visible thru topcoats.

Black speck - Flat bottemed dimpel with black speck at center.

Black yellow speck - Black speck enclosed in a yellow hello

Blisters - Circular holes and bubles in surface of cooled enamel.

Boiling - See blisters

Burn off - Localised areas of rough black oxide eruptions through the enamel coating

Carbon boil - Areas of fine grey or black specks

Chipping-off - A spalting or breaking off of enameled surface in flakes of various sizes.

Contamination by soil - Tight group of blisters often surrounded by smaller unbroken blisters.

Copperhead - Reddish brown spots

Crawling - Cracking & rolling back of fired enamel

Crocodiling - Parting of the surface into a geometric pattern, like a crocodil skin.

Dimples - Slight depressions in enamel surface, which do not reach the metal substrate.

Drainlines - Lines of thick enamel extending downwards from holes, lugs and corners.

Eggshell - egg shell appearance caused by many small bubbles bursting at the surface.

Faraday cage - Thin spraying of powder enamel inside sharp corners resulting in burning off/thru during firing.

Fishscaling - Small chips or scales coming off cooled enamel.

Furnace scale - Black particles typically laying on the enamel surface.

Gasatura - See grizzle

Grease mark - Rolling back of fused enamel to reveal areas of oxidised steel, irregular formbut rounded in sha

Grizzle - Coarse leathery or textured appearance to the surface.

Gun spitting - Raised rounded flattish conical areas, typically 3 to 6 mm in diameter.

Hairlining - Group of paralel lines.

Jumping - Chipping of the first coat during firing covercoat.

Lamination - A lineair defect comprising of a line of lumps or a single elongated ridge.

Lumps - Raised rounded areas 3 to 12 mm in diameter.

Metallization - Metallic iridescence on the fired enamel surface.

Orange peel - Wavy or granular appearance, very similar to an orance skin.

Pimply surface - See eggshell

Pin holes - Slightly diffused depressions that may reach the metal substrate.

Poor adherence - Enamel chipping off due to lack of bond with substrate.

Poor powder adhesion - Applied electrostatic powder enamel falling off during product handling prior to firing

Pop-off - Small, often circular, pieces of enamel showing poor adherence to steel surface. Often leaving a

Re-boiling - See blisters

Sagging - Wavy surface patterns after firing

Shorelines - Wavy parallel lines

Spalling - Fragmentation of enamel within coating layer.

Star marks - Dark star shaped defect, whereby the enamel is slightly raised between the arms.

Substrate damage - Usually visible as dents or ridges.

Tearing - See crawling.

Water stain - Light decoloration with a round shape.

Waterlining - Wet enamel washed away during application.

How to resolve enamel defects

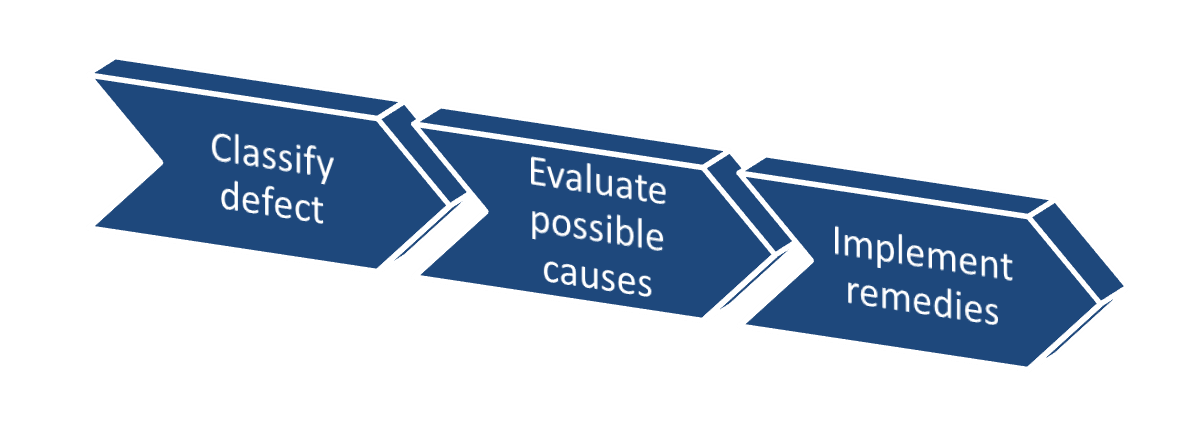

Resolving one of abovementioned enamel defects during an industrial manufacturing process requires a structured three steps approach.

Step I - Identify the right defect.

This may sound silly,but it is sometimes not easy to determine what is the exact defect. Incorrect identification will lead to the wrong causes & remedies.

Step II - Evaluate possible causes.

Focus your attention on the most logical ones first.

Step III - Implement appropriate remedies.

About Us

Ditmer Trading & Consulting BV is a family owned company, which was founded by Ronald Ditmer in 2007.

Our Managing Director & Owner has been personally involved in 50+ industrial porcelain enameling projects since 1984, while working respectively for Ferro (Holland) BV, Smit Ovens BV, Smit Sinus Enameling BV, Nordson Corporation and/or Ditmer Trading & Consulting BV.

We provide technical services, know-how and equipment to the porcelain (vitreous) enameling industry.

Technical Assistance

Due to the relative complex nature of enameling processes, it might not be easy to resolve an enamel defect.

Please feel free to contact us, via the form below, if you require any further information and/or assistance.

Palissander 141, 3315 MP Dordrecht, The Netherlands | e-mail: info@ditmer.nl | Phone : +31-786169877 | WhatsApp : +31-638-508743