Pickling may be done by means of immersing products into a series of tanks or by spraying inside a conveyorized corrosion-resistant tunnel. This second option is rarely selected due to significant investment & maintenance cost.

At immersion pickling systems products are typically placed into stainless steel baskets and then transported from one tank to the next by a manually operated hoist or by a handling robot.

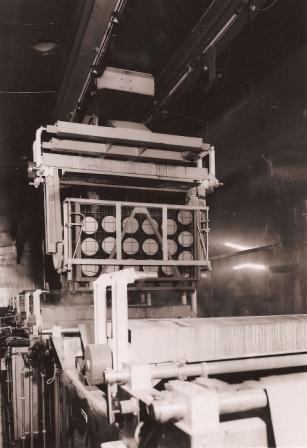

Below pictures of both material handling solutions.

Automatic immersion pretreatment system

with robot.

Manual immersion pretreatment system

with manual hoist